Machinery and Robotics Division

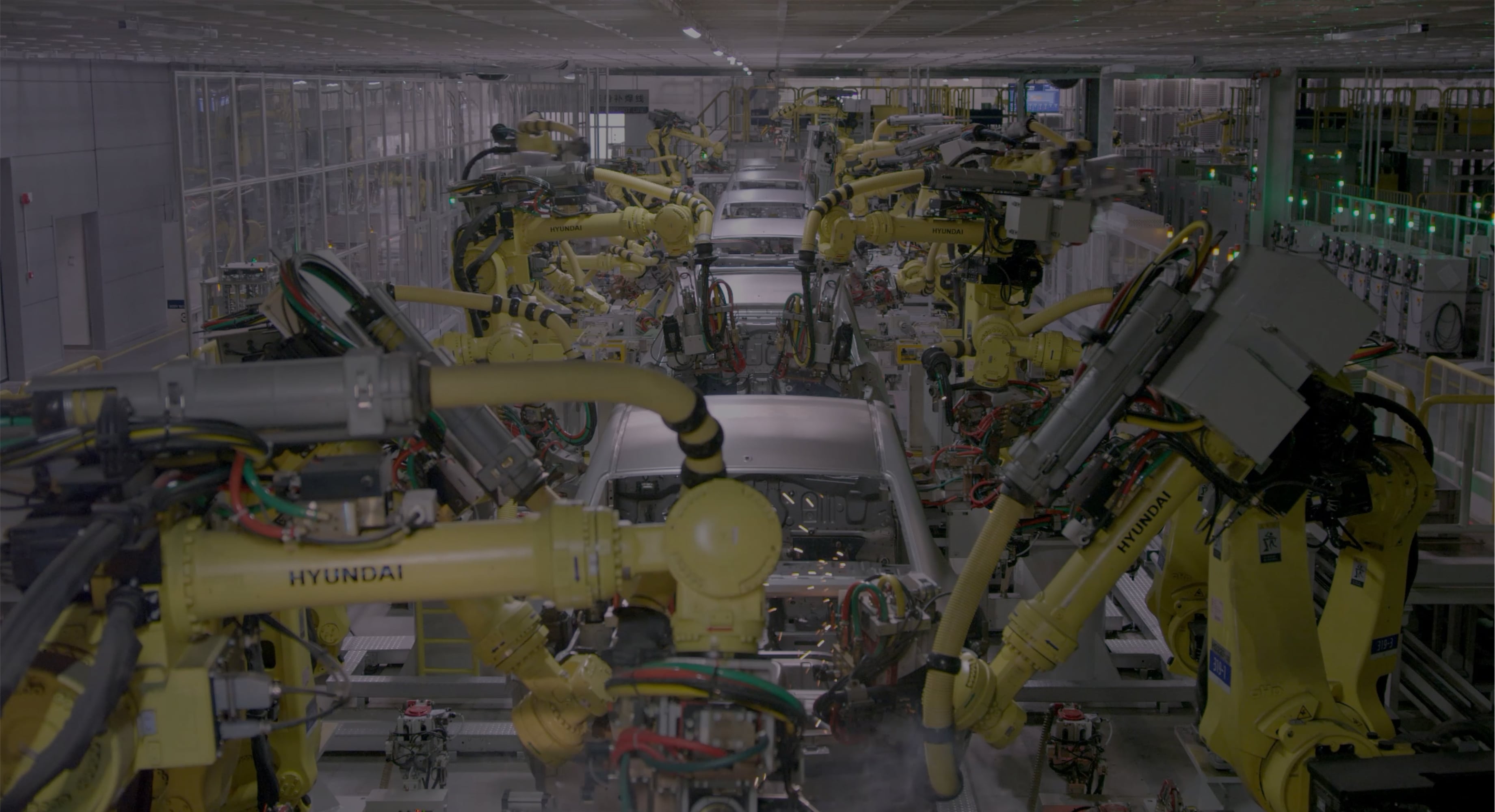

HD Hyundai Robotics

Largest Industrial Robot Manufacturer in Korea

HD Hyundai Robotics is Korea's leading industrial robot maker, encompassing a full range of services, including robotics and factory automation, engineering, installation, commissioning, and after-sales service (A/S). The company is dedicated to expanding its lineup with advanced robot technologies and driving high-efficiency automation, including providing total robotic solutions that feature mobile service robots for food and beverage delivery and disinfection. Through relentless research and development and innovative products, the company continues to grow alongside its customers and lead the robotics industry.

-

CEO

Kim Wansoo

-

Established

April 3, 2017

-

Revenue

KRW 214.9 billion (as of 2024)

-

Contact Number

+82-2-1588-9997 -

Address

50 Techno Sunhwan-ro 3-gil, Uga-eup, Dalseong-gun, Daegu, Republic of Korea

-

Sites

BUSINESS OVERVIEW

Industrial Robots

HD Hyundai Robotics commands the largest market share in the domestic industrial robot market. It promises customer satisfaction with differentiated quality and responsive A/S and are expanding into international markets with dealerships in China, India, the Czech Republic, Turkey, Brazil, and Russia.

Flat Panel Display Robot

Since starting the Flat Panel Display robot business in 2006 and successfully localizing production, HD Hyundai Robotics has become a key supplier to major display manufacturers. The company aims to achieve customer satisfaction through continuous production and product innovation in the FPD robot sector.

Controllers

HD Hyundai Robotics has developed robot controller models using proprietary technology and maintains a research team capable of adapting to new functions. Its controllers are prepared in various global languages and meet multiple international safety certifications, ensuring they are both user-friendly and safe.

Automation Systems

HD Hyundai Robotics provides efficient robotic automation systems to industrial sites, including press and engine assembly automation lines, painting/sealing automation lines, and heavy plate arc welding systems. The company also supports efficient automation solutions from design to installation and commissioning.

Smart Factory

The HD Smart Factory Integration Platform (H!Factory) connects all production equipment within a factory to collect, analyze, and manage data. It also interfaces with ERP and MES systems to manage production execution and performance, providing solutions for its clients' productivity, quality improvement, and facility management.